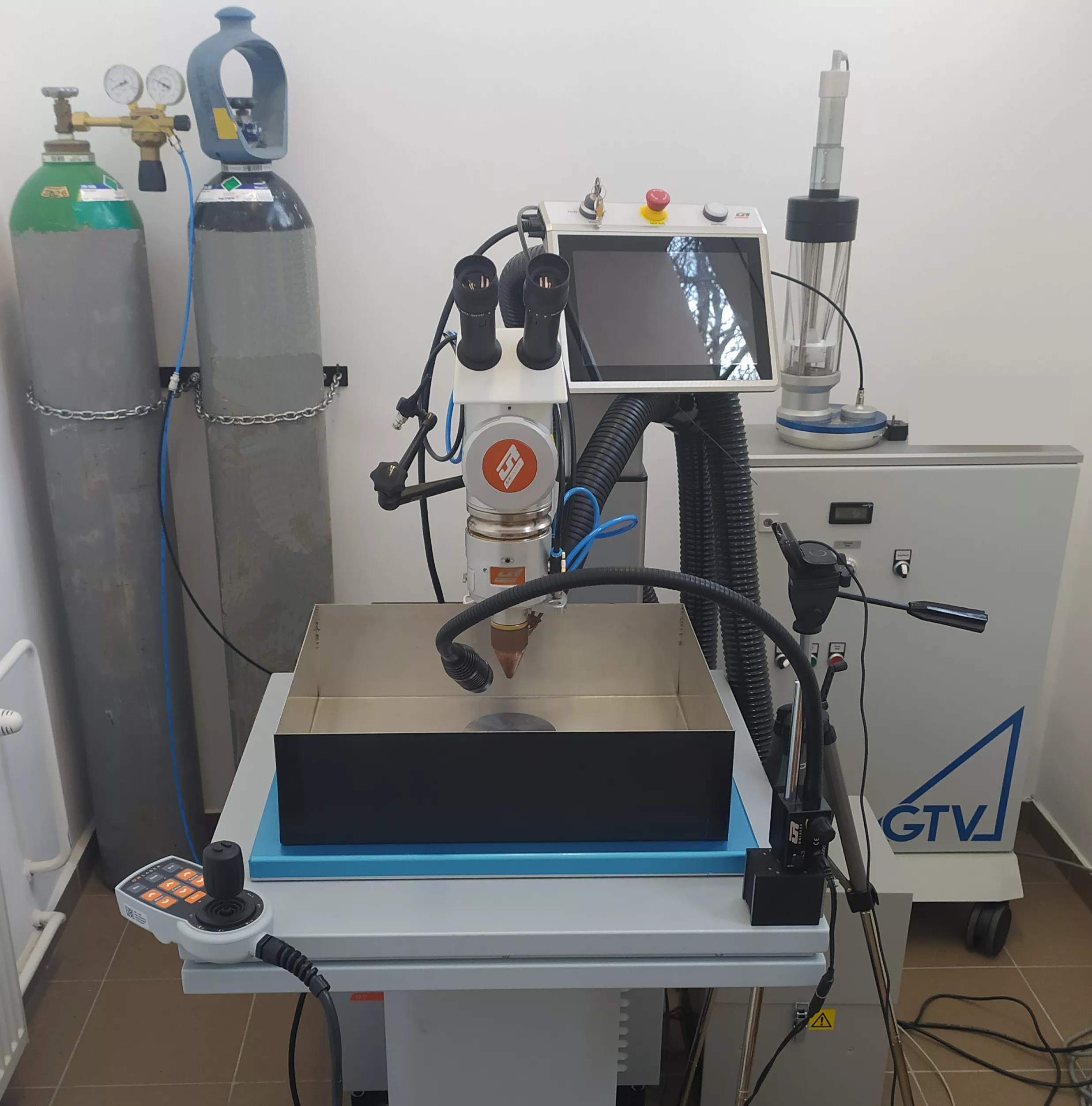

ELKH Wigner FK's Institute for Solid State Physics and Optics was involved as a consortium member in a project to develop a laser 3D metal printing machine called Automated Additive Manufacturing Laser Cell (RAM), which was awarded the Grand Prize in 2020 for its unique features and outstanding technical parameters at the 2020 Industry Days trade fair in Budapest.

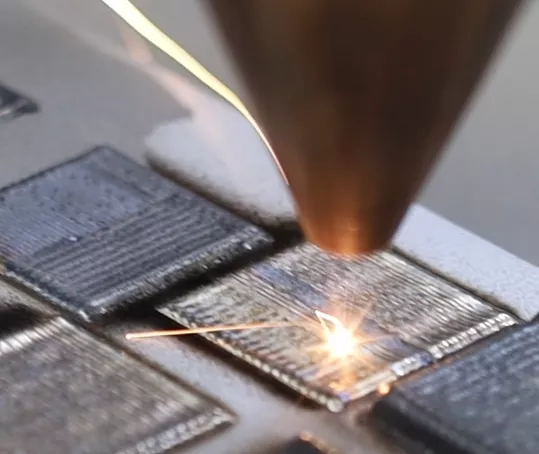

Within the framework of a project implemented under the leadership of LASRAM Engineering Kft. and the cooperation of Csepeli Szerszámgépgyár Ltd, the Laser Applications and Optical Measurement Techniques Research Group of the Applied and Nonlinear Optics Department of Wigner FK SZFI carried out research related to the integration of a laser 3D metal printer. During this, the researchers examined the effects of various technological parameters on the component construction process, analyzed the quality of the created surfaces and the correlations between the laser parameters and mechanical properties, established the optimal parameters for different metal powders to meet the required quality criteria, as well as worked on determining the physical and chemical properties and effects on health of aerosols released during the interaction between high-intensity laser beams and metal.

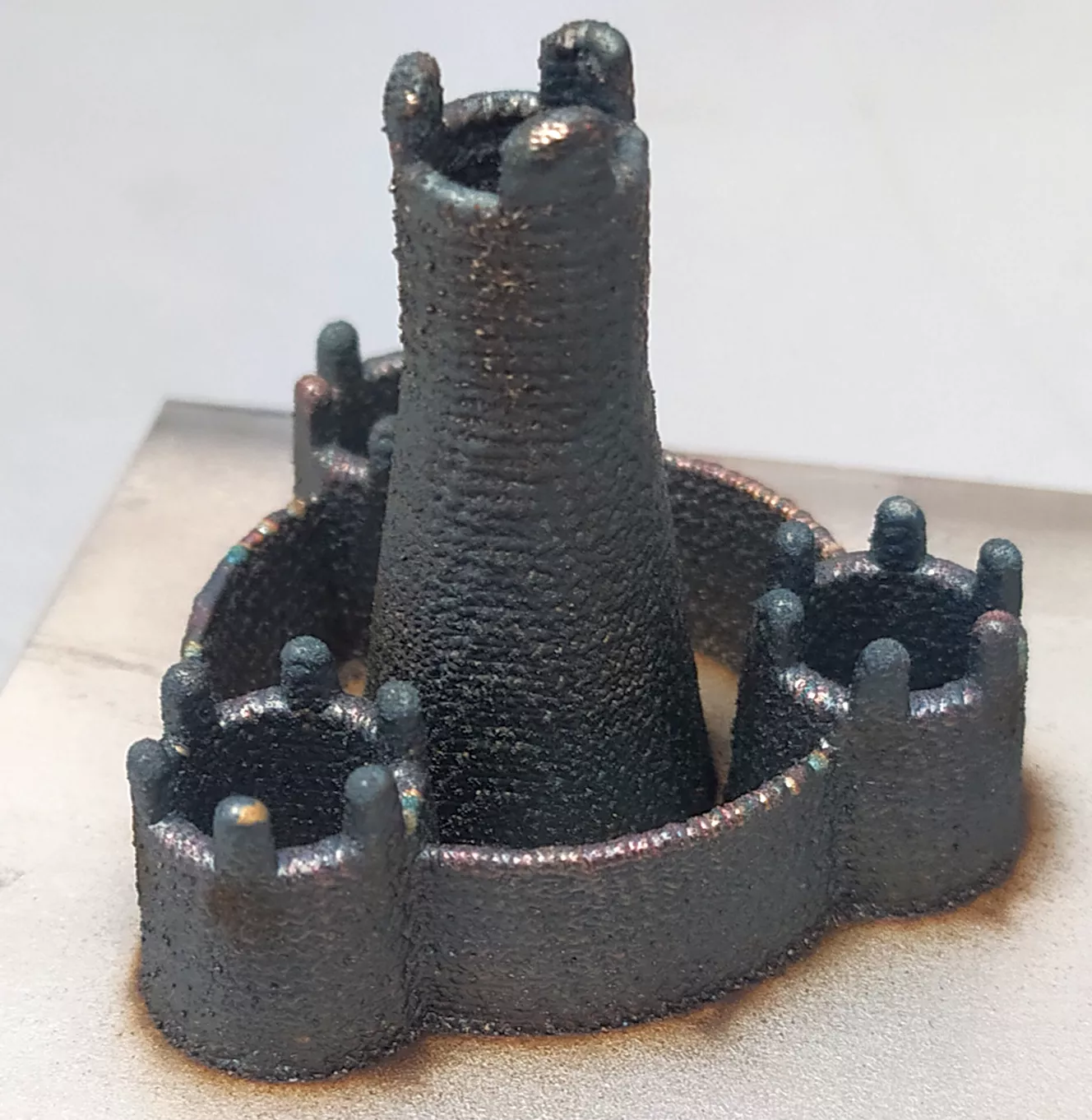

Laser technologies are becoming more prevalent in materials processing, mechanical engineering and fine mechanics. One new field is the use of modern lasers in additive technologies, where during metalworking, the final component is not formed by a practical reduction in the size of the material, as is the case with turning, milling or grinding, but is instead produced layer by layer from a metal powder that is applied by laser melting to a given surface using a special 3D metal printer. The advantage of this method is that it is possible to create – in an automated, material-saving manner and using digital technologies – particularly complex, three-dimensional curvatures, hollow structures with high tensile strength, and hardened wear-resistant surfaces and complex structures that are also lightweight, such as turbine blades for injectors and certain machine tool parts.

The development was implemented in project No. 2017-1.3.1-VKE-2017-00039, established within the framework of the NKFIH-funded Competitiveness and Excellence Cooperation invitation to tender.