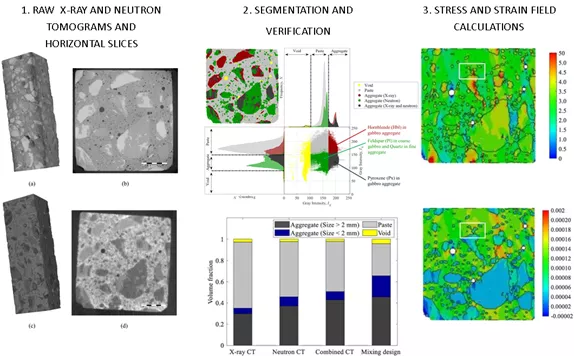

In the framework of the Visegrád Group (V4)-Korea Joint Research Program RADCON, researchers from the Centre for Energy Research (EK-CER), Hungary, Yonsei University, Seoul and the Institute of Fundamental Technological Research, Polish Academy of Sciences, Warsaw, successfully reconstructed the microstructure of concrete specimens by taking advantage of the complementary nature of X-ray and neutron computed tomography (CT). Neither tomogram alone was found to be suitable to properly describe the microstructure of concrete under this study. However, by merging the information revealed by the two modalities, and using advanced image segmentation, noise reduction, and image registration techniques, void, aggregate, and cement paste phases were successfully captured down to the images' spatial resolution, even though the aggregate consists of multiple minerals. This served as an input to the image-based finite element analysis calculations to demonstrate the effects of microstructure on stress concentration and strain localization.

Load-bearing structural materials, such as metals and concrete, are engineered to withstand forces of a given strength and orientation during their entire useful life. The design is usually supported by finite element calculations, where the properties of small volumes within the material are individually considered. This computational technique is already mature and reliable to predict the behavior of metals under loads, where homogeneity can be assumed with the exception of cracks, inclusions and voids.

Concrete is, however, a much more complex material as its microstructure is probably the most important characteristic in understanding material behavior. The compositions, sizes, shapes, and arrangements of the various phases present in concrete constitute its microstructure. Owning to the inherent complexity and uncertainty of phase distinction, the description of the microstructure is challenging, and therefore various experimental and numerical approaches have been developed to quantify the microstructural features of concrete.

Recent advancements in volumetric imaging technologies have made it possible to capture concrete microstructure in 3D by employing X-ray and neutron computed tomography (CT). As X-ray attenuation coefficients mainly depend on the atomic number and the material density of the material, void spaces in concrete provide a high contrast and can therefore be accurately identified. In contrast to X-rays, the attenuation of a neutron beam is rather sensitive to hydrogenous components.

The goal of this study was to reconstruct concrete microstructure with polymineral aggregates and use it for finite element calculations. This was achieved using the complementarity of X-ray and neutron CT images in conjunction with image segmentation, noise reduction, and image registration techniques. The fine aggregate consists of quartz, while coarse aggregates are gabbro rock fragments containing more mineral phases. This composition results in various attenuation coefficients among aggregate clasts, and even inside gabbro rock fragments.

Based on feature-based image registration, X-ray and neutron CT images are fused, and concrete microstructure is successfully reconstructed, at least down to the image resolution. Based on the grayscale intensities of each CT image, three phases of air void, aggregate, and paste are identified. The reconstructed concrete microstructure is validated by comparing cumulative volume fractions, i.e. the coarse aggregate volume fraction of a concrete microstructure agrees well with that of the mixing design. Additionally, the influence of a reconstructed microstructure on the localized stress and strain fields in concrete is computationally demonstrated using a finite element simulation.

The study concluded that advanced imaging techniques are highly applicable to deriving an accurate representation of a 3D concrete microstructure, and ultimately to obtaining more realistic internal stress calculation results even for such a composite material.

This work was supported by the Visegrad Group (V4)-Korea Joint Research Program. HK, TR, and KP acknowledge the support of the National Research Foundation of Korea funded by the Ministry of Science, ICT & Future Planning (grant number: 2017K1A3A1A67015884). The Hungarian co-authors acknowledge project No. 127102 RADCON, which was implemented with the support provided from the National Research, Development and Innovation Fund of Hungary, and financed under the NN_17 V4-Korea funding scheme. The Polish co-author was supported by the Polish National Centre for Research and Development (Project V4-Korea/2/2018).